Driving Innovation with Umpire 41:

Testing Moisture Effects on Battery Circuits

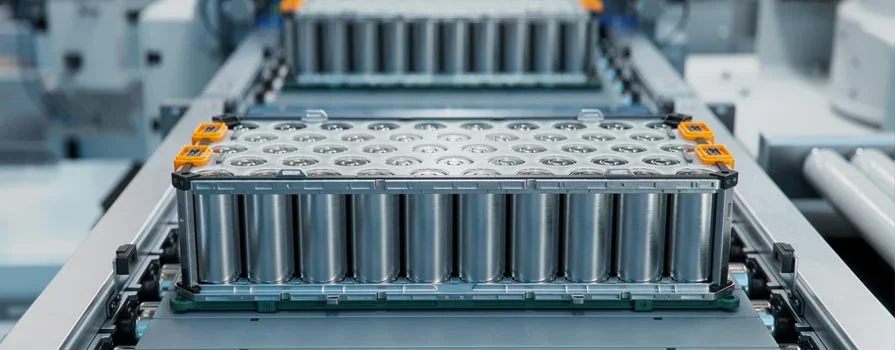

Our team of investigators is always looking for new ways to push reliability testing further. Our latest work with the Umpire 41 system zeroes in on something every engineer wrestles with: battery circuit performance and battery drain under environmental stress.

Right now, our team is wiring up a new chamber to explore how thermal cycling impacts moisture ingress in battery circuits. The goal? To better understand how environmental conditions drive moisture into both surface and active components—and to build a test protocol that helps identify risks earlier.

Why Temperature Cycling Matters

Moisture is one of the biggest long-term threats to electronic reliability. By controlling how we expose a device to temperature swings, we can accelerate environmental effects in a way that standard monitoring can’t fully capture.

For example, we’re looking at a cycling range of -25°C to +65°C. As we bring the part through dew point, then power it back up once it cools from 60°C to around 40°C, we can monitor its behavior for an hour. This gives us a detailed look at where and how moisture is coating the package.

The Umpire 41 platform lets us observe battery drain and circuit activity with precision. Instead of waiting for slow, natural degradation, we can apply controlled stress and gather data much faster. The result is a clearer, earlier picture of how devices respond to real-world conditions.

What’s Next

This work is more than a one-off experiment—it’s the foundation for a new Foresite test method. With support from potential partners, we’re aiming to accelerate and monitor moisture effects. That means creating a repeatable protocol that helps manufacturers understand risks earlier in the design and production cycle.

By combining Umpire 41 technology with innovative testing strategies, we’re not just monitoring performance—we’re shaping the future of reliability testing.