Why LED Reliability Isn’t Guaranteed — And What Engineers Miss

By Foresite, with insights from Lead Investigator Paco Solis

LEDs promise exceptional efficiency and long lifespan, but their reliability is far from a guarantee.

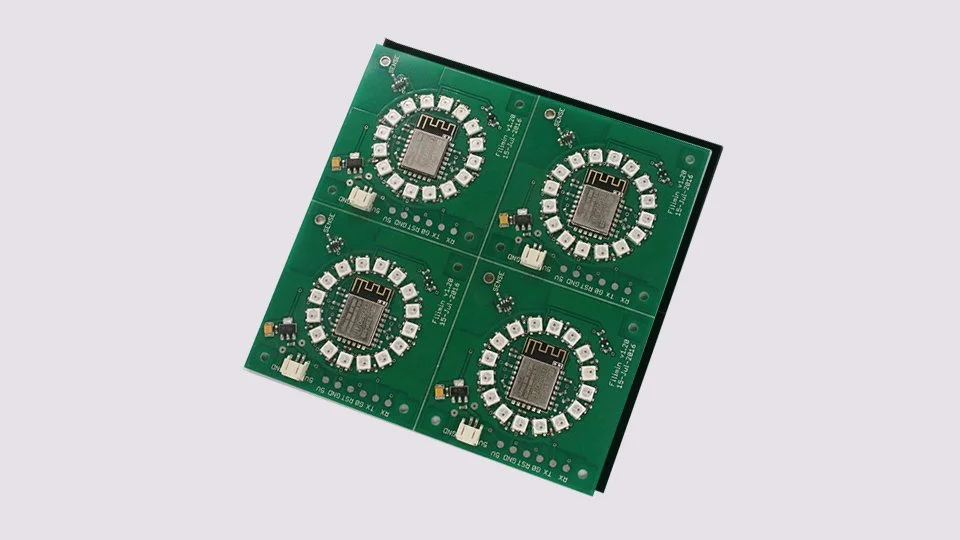

Especially as products get smaller and thermal demands increase, LEDs become one of the earliest indicators of deeper design problems.

The Thermal Reality Behind LEDs

LEDs work by emitting photons across a semiconductor junction. Any energy not emitted as light becomes localized heat — heat that must be carefully dissipated through the chip, package, interconnects, and PCB. When that pathway is constrained or cost-reduced, LEDs degrade quickly: dimming, color shifting, and eventually failing.

“Every electron that doesn’t become a photon becomes heat — and that heat has to be managed at every level of the LED package.” — Paco Solis

Even small temperature increases at the junction can cut lifespan dramatically. Good PCB stack-up, proper solder joints, and real airflow matter far more than spec sheets suggest.

Material Compatibility: The Hidden Failure Mode

LED assemblies combine diverse materials — semiconductors, encapsulants, solder alloys, phosphors, plastics — each expanding and aging differently under heat. When thermal stress is repetitive, these mismatches turn into cracks, delamination, discoloration, and reduced optical output long before the LED “fails” outright.

“Material compatibility is critical. The wrong combination can turn thermal stress into mechanical failure.” — Paco Solis

This is why cleanliness, assembly quality, and long-term environmental exposure testing play such a major role in LED reliability work at Foresite.

Cost Pressure and Reliability Trade-Offs

Today’s LED market is under intense cost pressure. Cheaper substrates, thinner copper, lighter heat-sinking, and lower-grade encapsulants make it harder for LEDs to perform as needed. And because LEDs are expected to last, customers experience premature failures as a breakdown of trust — not just a component issue.

“Just like printed circuit boards, the amount of profit is being squeezed out of the industry based on cost.” — Paco Solis

The result is a landscape where LEDs look great on paper but underperform in real-world conditions unless designers actively push for reliability-minded choices.

Common Failure Triggers Foresite Sees

Rising junction temperature from inadequate thermal pathways

Encapsulant yellowing or cracking under heat exposure

Solder fatigue from expansion-rate mismatches

Ionic contamination accelerating corrosion at temperature

Driver heat or enclosure design trapping thermal energy near the LED

“LED reliability is an ecosystem problem. When one part fails to support the others, LEDs show the symptoms first.” — Paco Solis

Final Takeaway

LEDs are efficient — but they aren’t invincible. Their reliability depends on thermal engineering, materials science, cleanliness, and the overall system environment. When LEDs dim, discolor, or fail early, they’re rarely the true cause of the problem. They’re just the messenger.

Foresite’s analytical tools and failure-investigation expertise uncover these issues before they reach your customers — and long before they become costly field returns.